4. How to Manage Filling orders

WorkThe filling manager possesses the ability to fill empty cylinders in progressa filling station, provided they are not defective. When an order is generated in the back office, it will be displayed in the 'filling orders' section of the stock tab.

To proceed with the order, the user needs to click on the specific order that needs to be fulfilled. Upon clicking on the order, the filling details will be displayed, providing the necessary information to carry out the filling process.

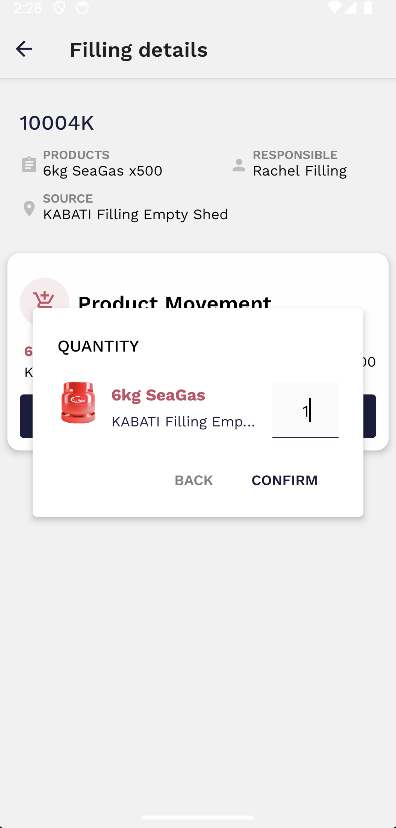

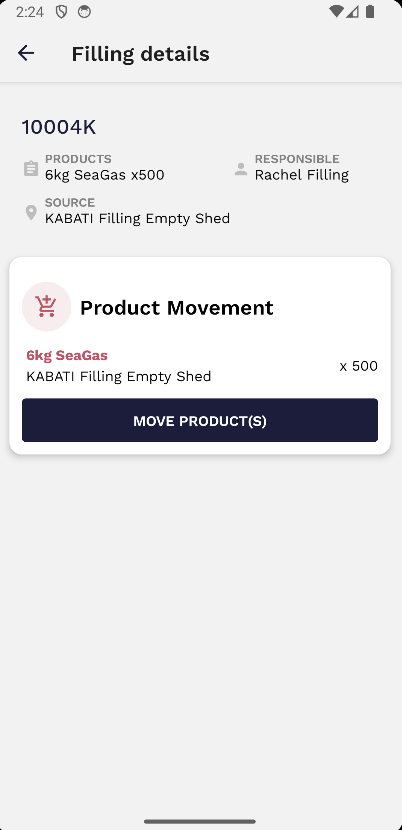

Afterward, the user should choose the 'move product(s)' option. This will trigger a pop-up where the user must confirm the quantity of cylinders that are going to be filled.

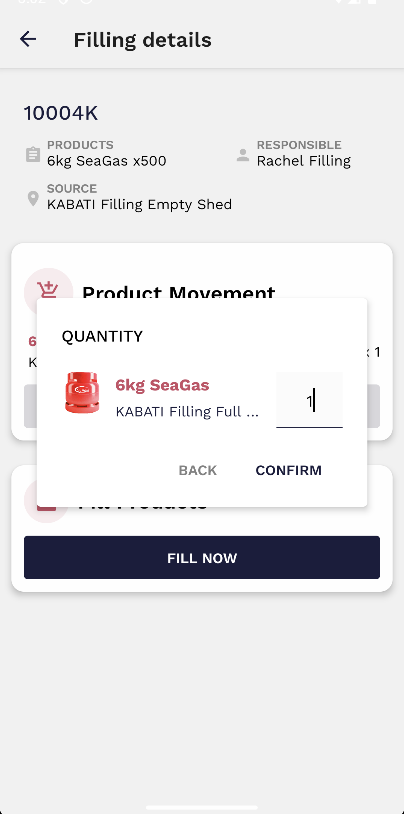

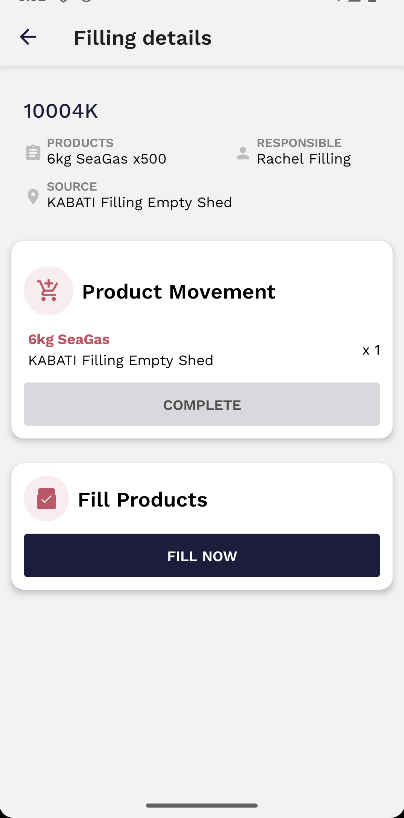

Additionally, this movement must also be authorised by the container coordinator at the location where the empty cylinders are stored. Once the confirmation is signed by the coordinator, the product movement initiated by the filling manager will be marked as 'complete.' At this point, the filling process can commence.

Next, the user should select 'fill now' and input the quantity of cylinders being filled. Once the filling manager clicks 'confirm,' the status of the cylinder will transition from empty to full.